The method of spray drying is used for drying many thermally-sensitive materials (foods and pharmaceuticals). This method involves rapid drying of a liquid oi slurry with a hot gas to produce dry powder.

Principle

Spray dryer involves atomizing the fluid to be dried into fine droplets. These droplets are radially subjected to a moving stream of hot gas, thus resulting in an immediate increase in their temperature. Rise in temperature results.in the drying of fine droplets in the form of spherical particle formation. This process completes within a few seconds before the droplets reach the dryer wall.

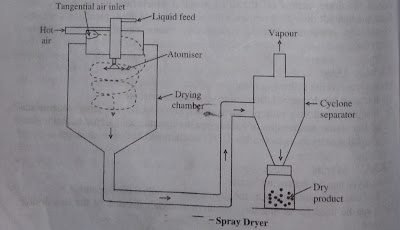

Construction

A spray dryer consists of a large cylindrical drying chamber droplet size having a short conical bottom. This chamber is made up of stainless steel with 5.5-9.0m diameter and 25m or more height. The roof of the chamber has two inlets. one for the hot air and the other for spray-disk atomizer (diameter is about 300mm) rotating at a speed of 3,000-50,000rps. A cyclone separator is connected to the bottom of the dryer.

Working

A material in a spray dryer can be dried in three stages:

1) Atomization of the Liquid to Form Liquid Droplets:

The feed is introduced into the drying chamber through the atomizer (to form fine droplets) either tilework the gravitational force or by using a pump. The droplet form is the factor on which-the properties of the end product depend, therefore an atomizer should be selected properly. There are a variety of atomizes which can oral drug be used such as pneumatic atomizer, pressure nozzle, and spinning disc atomizer. The rate at which the feed is introduced should be such that the droplets completely dry before reaching the drying chamber walls, and also the product should not be overheated.

2) Drying of the Liquid Droplets:

Hot air introduced in the drying chamber through an inlet dries the fine droplets. The droplet surface gets immediately dried up forming a tough shell, while the liquid inside these droplets escapes by diffusing through the shell at a particular rate. Concurrently, heat transfer takes place from outside to inside at a rate greater than liquid diffusion rate. This increases the heat inside the chamber allowing the liquid to evaporate at a faster rate. This in turn raises the internal pressure spray drying process making the droplets swell, decreasing the shell's thickness, and increasing the permeability for vapor. The shell ruptures letting the internal pressure escape if it is neither elastic or permeable. The input stream is sprayed air temperature should be such that the droplets completely dry before reaching the drying chamber walls, and also the product should not be overheated.

3) Recovery of the Dried Product:

The droplets follow a helical path driven by the atomizer's centrifugal force. While travelling through this path the droplets get dried up and then fall at the conical bottom. These processes take a few seconds to complete. The particle size of the end product ranging from 250mm depends on the feed's solid content, liquid's viscosity, feed rate, and disc speed. The evaporating capacity of spray dryers of maximum particle size distribution size is about 2000kg/hour.

Uses

Spray dryer has the following uses:

1) It is used for drying heat-sensitive substances.

2) It- is used for drying suspensions (such as starch, barium sulphate, and calcium phosphate) and solutions.

3) It is used for drying coffee, soap, detergent, and plasma.

4) It is used for drying fruit juices, milk, and its products.

5) It is used for drying hexamine, borax, sodium, phosphate, gelatin acacia extract, ferrous sulphate, adrenaline, citric acid, and ascorbic acid.

Merits

Spray dryer has the following merits:

1) It is continuous and a rapid process as it takes only 3-30 seconds.

2) It requires less labor (i.e., the labor cost is low) as the function of an evaporator, a crystallizer, a dryer, a size reduction unit, and a classifier is combined.

3) An end product of uniform and controllable size can be obtained by using a Suitable atomizer. The product is free flowing and is in the form of uniform spheres, thus, convenient for the tableting process.

4) The fine droplets obtained provide a large surface area for both heat and mass transfer, thus, possess excellent solubility.

5) In a single step, solution, suspension, or thin paste can be dried to a final product ready for packaging.

6) Sterile products can be dried suitably.

7) Reconstituted products and the fresh material are almost similar.

8) The globules of an emulsion can be dried with the dispersed phase inside and the continuous phase outside. On reconstitution, the emulsion forms.

Spray dryer has the following demerits:

1) It is expensive.

2) Walls of the drying chamber also get coated.

3) The material cannot be recovered completely.

4) It requires a large floor space as it is bulky, and ancillary equipment (fans, heaters, separators) are also attached to it.

5) Thermal efficiency is low (5000 BTU/Cb water evaporated) due to the loss of hot air in the environment.

6) Storage problems occur as it produces bulky products.

For extra notes;

Mechanism of Drying Process

Introduction

Drying involves moisture removal from a substance fluid nozzle without affecting its physical structure and appearance. On heating a moist solid, the drying air moisture evaporates at or near the solid surface. This evaporation of small droplets of moisture from the product to be dried is possible because of the external drying medium (usually, air or a hot gas). Heat and mass transfer are the principles governing the process of drying. In drying (a diffusional process), the surface moisture liquid stream separates from evaporated and active pharmaceutical ingredients transferred to the surrounding medium. The moisture from the interior of the solid comes to the surface as soon as the milk powders surface moisture evaporates.

The nature, type, pore structure, aggregation state, and drying rate of the substance (to be dried) decide the mechanism of moisture amorphous solid transport within it.

Following mechanisms are involved in drying process:

1) Transport by liquid or vapor diffusion,

2) Capillary section, and

3) high Pressure induced transport.

Drying process involving different stages is dominated by different mechanisms.

Mechanism of drying gas is discussed under the following two heads:

1) Equilibrium relationship, and

2) Rate relationship

For more pharmacy notes:

Visit;

What is the typical value of the Internal pressure of the spray dryer

ReplyDeleteCrystallizers are used in industries to separate liquid and solid components. They are also one of the most important parts of the processing equipments as they are capable of producing high purity products at comparatively low energy inputs.

ReplyDeleteheat exchanger makers

heat exchanger

made in usa distillation equipment