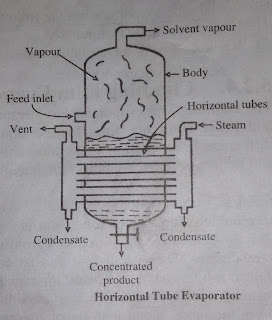

Horizontal Tube Evaporator:

Horizontal tube evaporator is a modified from of open pan evaporator. In this the pan is enclosed with in a vertical cylinder. Bottom portion of this cylinder contains the liquid to be evaporated in which horizontally arranged heating tubes are immersed. However, in this evaporator circulation of liquid is poor.

Principle

In horizontal tube evaporator, steam is introduced into the horizontal tubes dipped in the liquid to be evaporated. Steam in the tubes provides heat to the liquid outside the tubes. The liquids gets heated up, thus evaporating the solvent which escape from the top of the evaporator. The concentration products is collected from the bottom.

Construction

Horizontal tube evaporator consist of a large cylindrical body made up of cast iron or plate steel. It has a conical or dome-shaped top and bottom. Its average size range from 1.8-2.4m diameter and 2.4-3.6m length.

A steam compartment is present at the lower part of the body. One end of this compartment has a steam inlet and the other end has an outlet for non-condensed gases. At both the end of the bottom portion of the compartment, a condensate outlet is present. Within the steam compartment, 6-8 heating tubes made up of stainless steel are horizontally placed. Length of the tubes is such that they project about 25mm beyond the tube sheet on both ends. Width of the steam compartment is half the diameter of the body.

Above the steam compartment, a feed inlet is present. At the top of the cylindrical body, a vapour outlet and at the bottom an outlet for concentrated products are present.

Working

The feed is introduced into the evaporator till the steam compartment gets immersed in the liquid to be evaporated. Steam is introduced into the steam compartment through the provided inlet. As the steam passes through the horizontal tubes, they receive heat from the steam and transfer into the liquid outside the tubes. The steam condensate passes through the provided outlets at the bottom end of the steam compartment. The feed absorbs heat and the solvent evaporates by converting in to vapour, which escapes through the outlet at the top. This process continues till a concentrate liquid is obtained which is collected from the product outlet at the bottom.

Use

Horizontal tube evaporator is used for non-viscous solution which on evaporation do not deposit scales or crystals, e.g., cascara extract

Merits

Horizontal tube evaporator has the following merits:

1) The cost per square meter of heating surface is less.

2) It is easy to install.

3) The tubes can be easily removed.

Demerits

Horizontal tube evaporator has the following demerits:

1) It requires a large heating area.

2) It is not used for thermolabile material and crystalline products.

Factor affecting evaporation

The following factor affects the rate of evaporation:

1) Surface Area: Being a surface phenomenon the evaporation rate increases with the increase in surface area. for example, wet clothes dry faster on spreading them out.

2) Temperature: The evaporation rate increases with increase in temperature as the kinetic energy of more number of molecules increases, thus facilitating them to go into the vapour state.

Evaporators are classified as flooded type and dry type depending upon whether liquid refrigerant covers all heat transfer surfaces or some portion is having gas vapour being superheated.

ReplyDeleteevaporators supplier in usa

evaporators services

evaporators services

evaporators

Great post

Evaporators are utilized in a variety of refrigeration applications and hence have a variety of designs. The architecture of the evaporator, the technique of feeding the refrigerant, the direction of air circulation around the evaporator, and other factors may all be used to classify evaporators. The evaporators have been categorized depending on their construction.

ReplyDeletecrystallizer

evaporator

evaporatora